Moose, Brad, and I met to drill the leg/ankle to foot pivot holes in the outer and center legs. After the much debate and comparing outer and center leg hole positions and sizes to every R2 design known to man, we finally settled on the JAG hole position and size for both the outer and center legs/ankles. We found that every bit Moose and Brad had was either too long or did not have a sharp enough tip to ensure we would get the exact position we needed to drill. No choice, we had a field trip to Westlake Hardware where I bought a ½” forstner bit. I love this thing!!! It is accurate, it clears debris as it drills, and it doesn't vibrate the piece of wood you're working on.

We laid the JAG template over the finished outer leg piece and used a nail to mark the center position of the pivot hole.

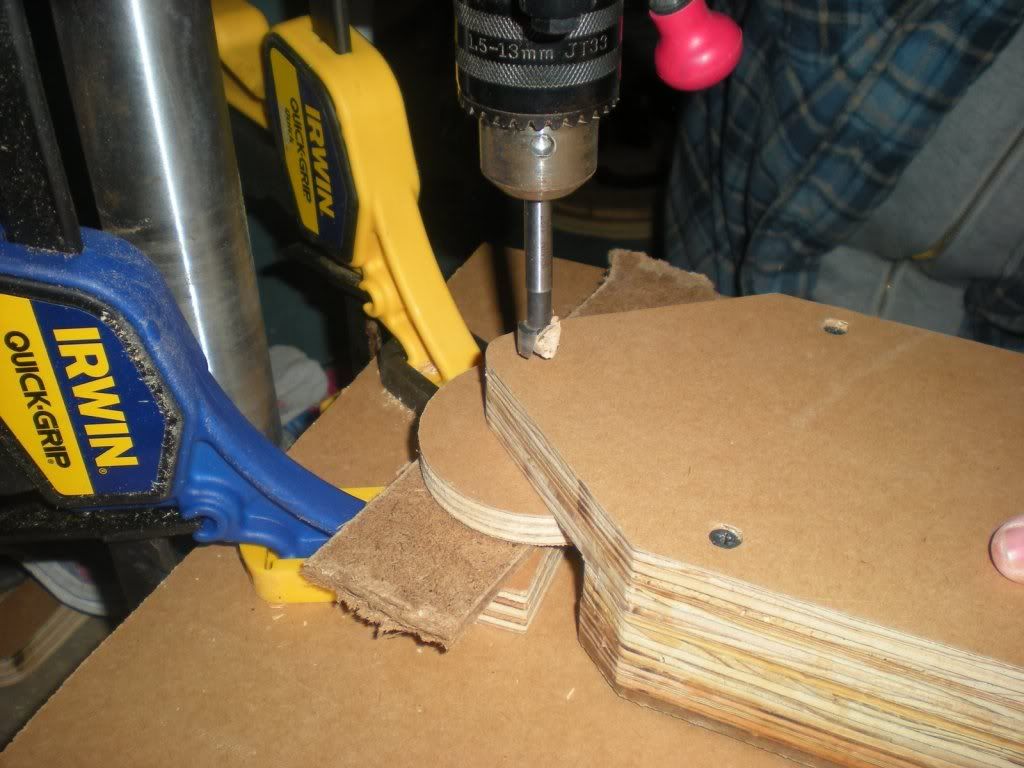

Because our legs already had the hardware attached and the drill press plate was too small to keep our legs steady, we built a much larger work surface to keep the legs steady as we drilled.

Here we go. This is a three person process once the drill is turned on. One person to hold the leg in place, one person to make sure this unbalanced mess doesn't tip over, and one person to run the drill. Brad is taking the picture; otherwise he would be holding the drill.

We do pretty good work. The holes are dead on accurate.

The center leg was a little more tricky to line up. We had to cut out a separate center leg template before we could mark the center with a nail hole. The drilling process was the same and the result looked great.

No comments:

Post a Comment