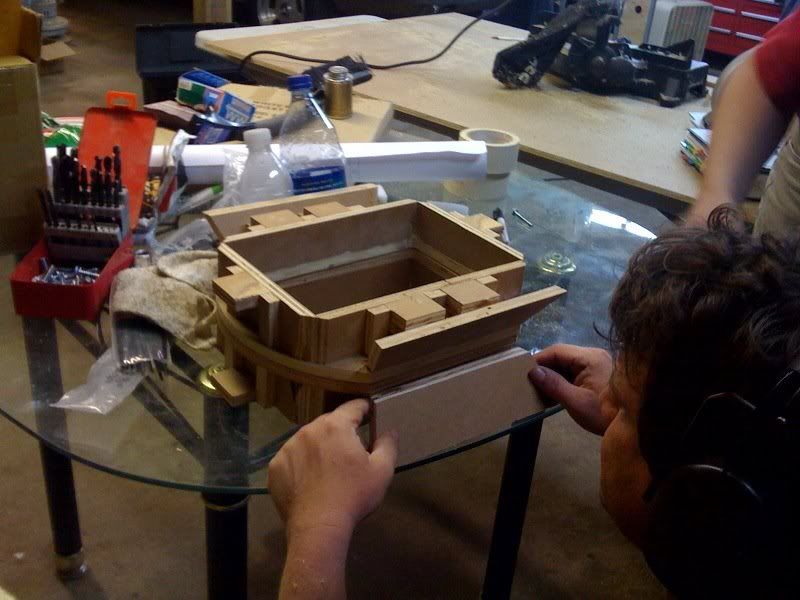

The Rockler Bearing is a Lazy Susan mounted to the top of the frame that allows the dome to turn 360°. The outer ring is attached to the frame and the inner ring holds the dome. The bearing comes with eight pre-drilled holes in the bottom of the outer ring with plastic spacers/feet used to prevent it from resting completely on the surface it is mounted to. Four of the plastic spacers were removed and the holes were drilled completely through the outer ring.

Once the holes were drilled in the outer ring, it was turned over, centered on the wood frame (done by feel because this will probably have to be adjusted later after the skins are added), and four 1½” sheet metal screws were used to attach the Rockler Bearing to the frame (no pilot holes where drilled). Two washers for each screw were added to the underside of the outer bearing ring to match thickness of the plastic feet of the outer ring. The mounting screws stick out the bottom of the frame slightly, so the should be replaced later with 1¼” screws.

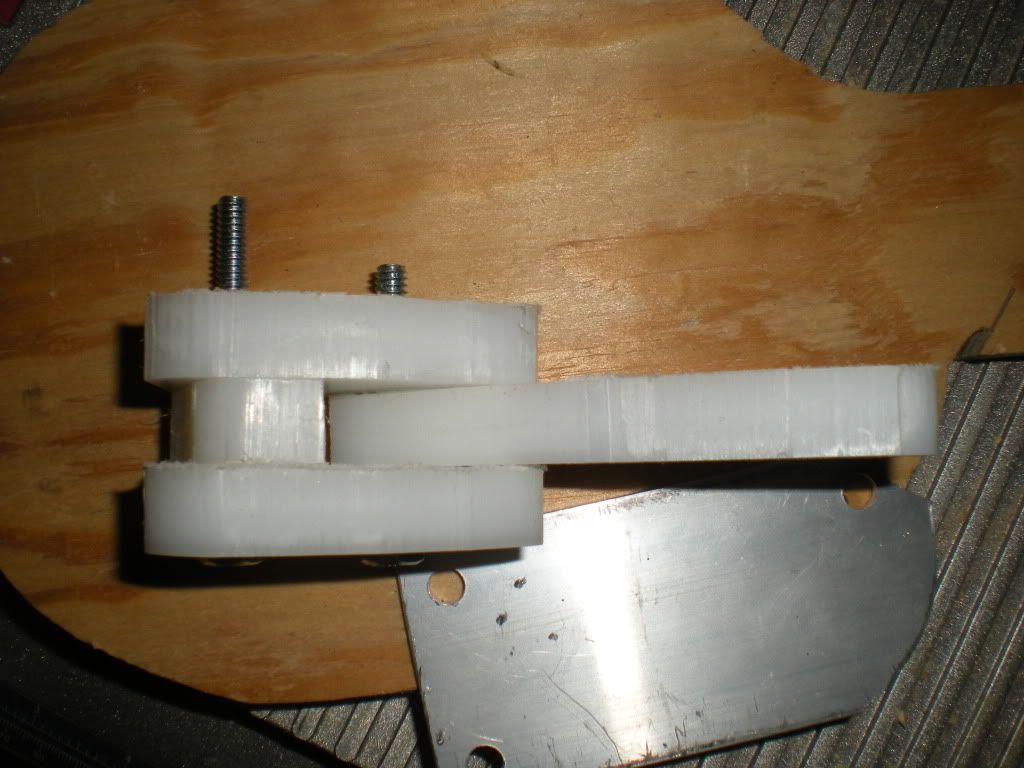

Six 2" bolts where inserted in the six countersunk holes on the underside of the inner ring. The bolts where held in place by two nuts. The plate that holds the dome will rest on the top of the nuts. Depending on how needed dome height, more nuts can be added to the six bolts.

After the ring was installed I checked to see how the bearing turned. It seemed a little stiff, so I loosened the outer ring bolts slightly and it turned easier.