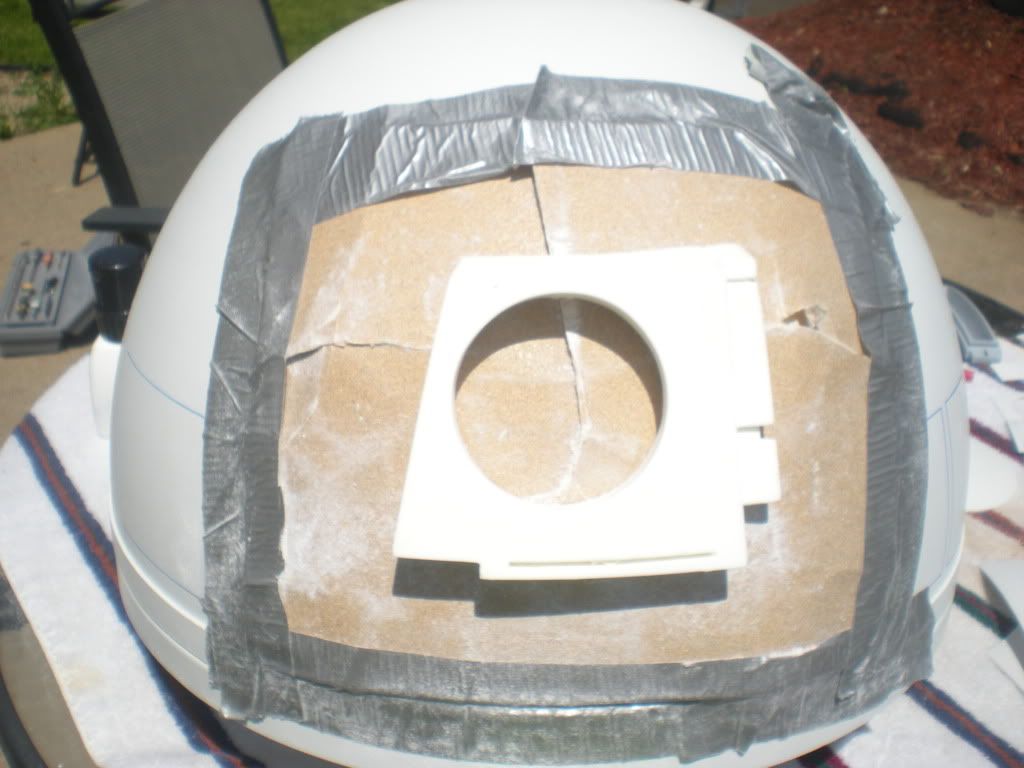

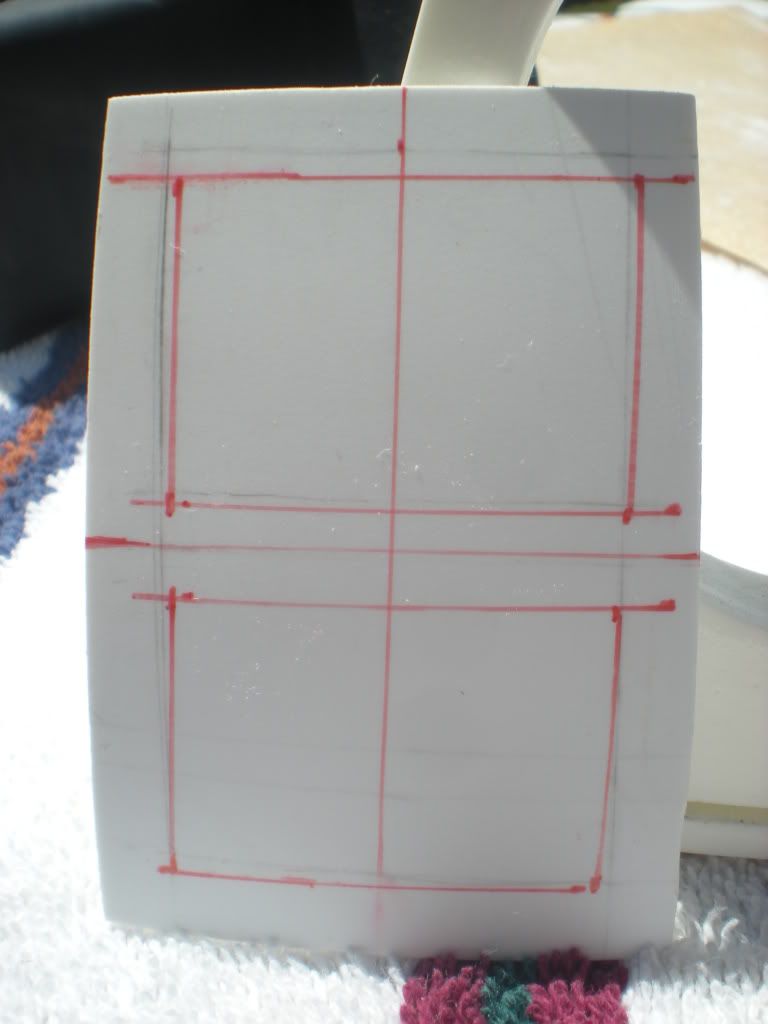

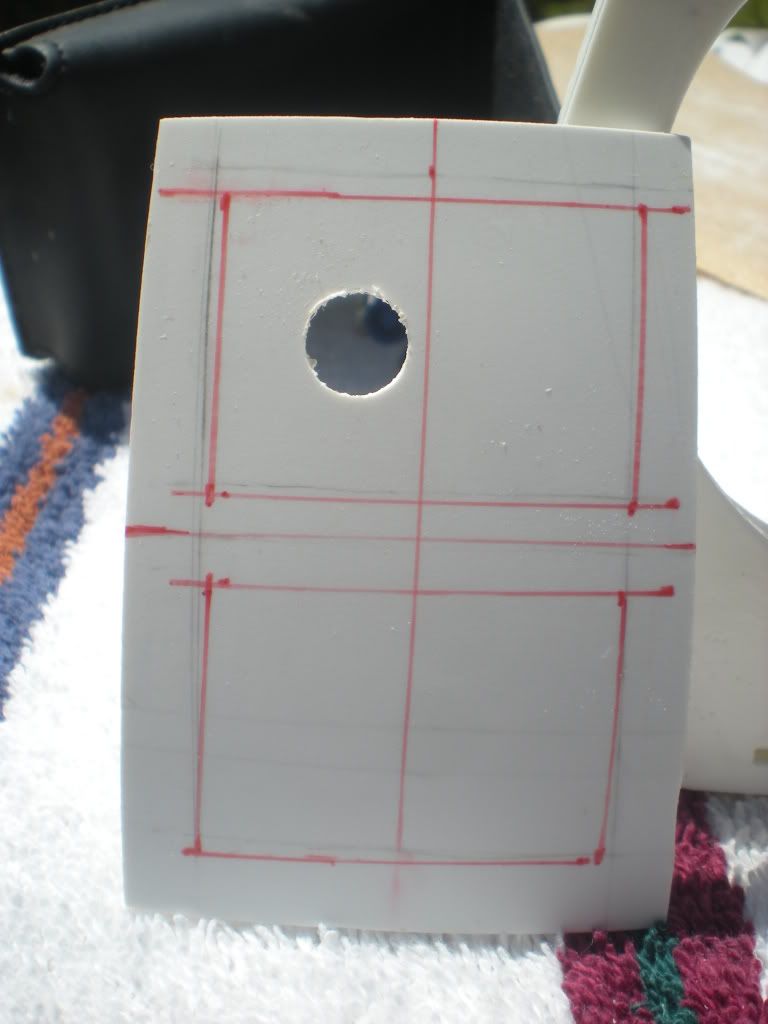

I've been nervous about cutting the inner dome; but tonight, I decided to go for it. I've done all the reading on Astromech.net I can, so there is no more excuses to delay. I put the inner and outer dome together one last time and traced the location of the top dome plate on the inner dome so I could line it up when gluing. I used a Dremel to cut along the top line, sanded the edge to make sure it lays flat against the inside of the outer dome when it is glued, and gave the inner dome piece a light sanding with 220 grit paper.

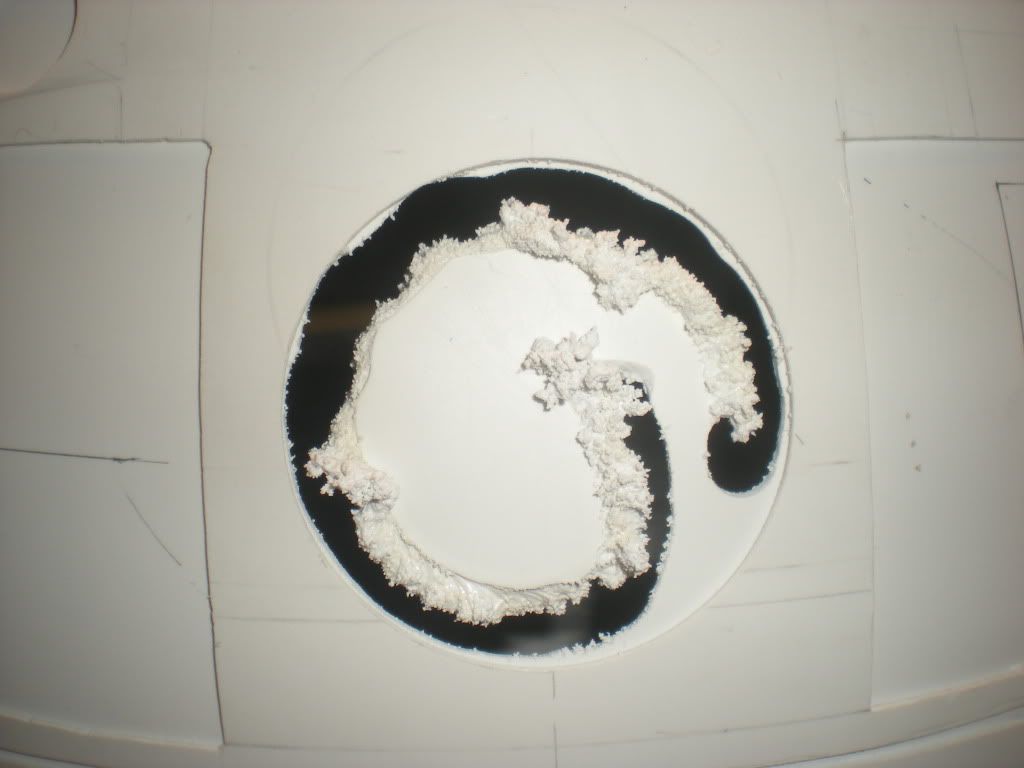

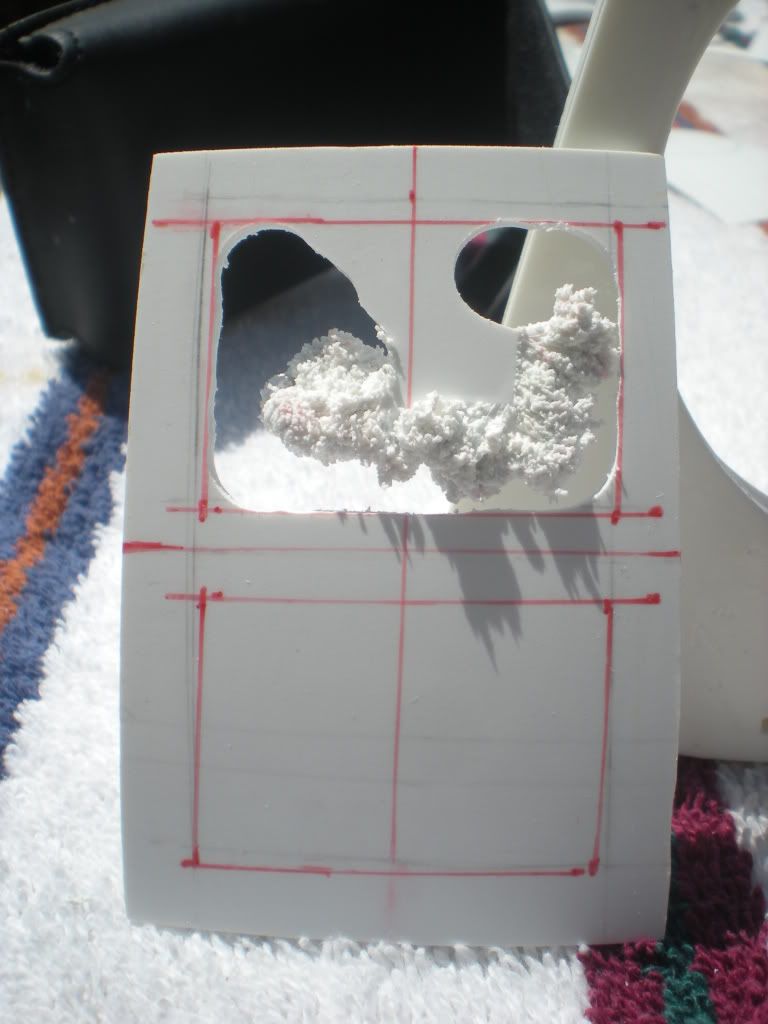

WHAT A MESS!!! Tech Bond was NOT the material to use to glue the dome together. I put the glue on the inside of the outer dome and I sprayed the activator on the outside of the inner dome. It was too hard to line up the dome piece before I accidentally touched the dome pieces together in a couple locations. By the time everything was lined up the activator had evaporated and the glue had dried so a bond was not made. I had to re-sand the inner and out dome pieces, put the dome pieces together, and glue the dome section by section.

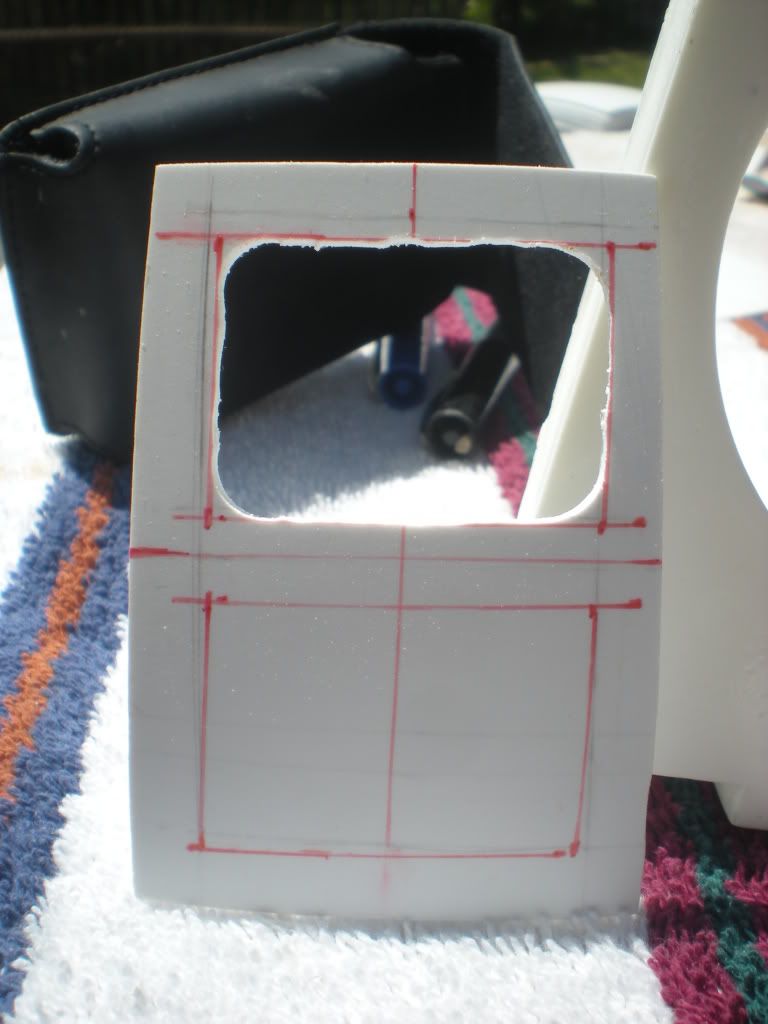

I decided to do something different when gluing the lower portion of the inner dome to the outer dome. I decided to use Blair Artist's Mounting Adhesive. This will eventually make a permanent bond; but in the interim, I can move the pieces into place without fear of quick drying. I cut the inner dome along the remaining line (to leave a gap between the upper and lower inner dome sections), sanded the edge to make sure it lays flat when gluing, and gave the outside of the inner dome a light sanding with 220 grit sandpaper. This worked much better. I then glued the upper edge of bottom dome piece with Tech Bond to make sure it didn't move until the artist's adhesive set.